DIY: The 1000-pound Front Spindle Upgrade

Bear the weight of a new loader by beefing up your garden tractor’s front-end spindles.

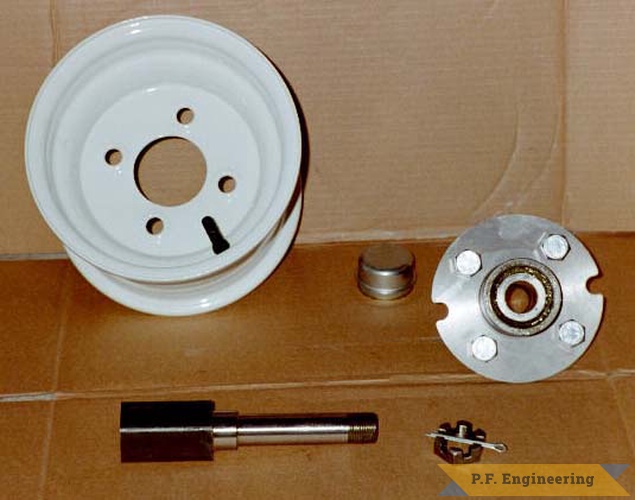

Parts needed for this project:

Norman explains how to upgrade the spindle on his Cub Cadet 149.

How to do it:

Step 1

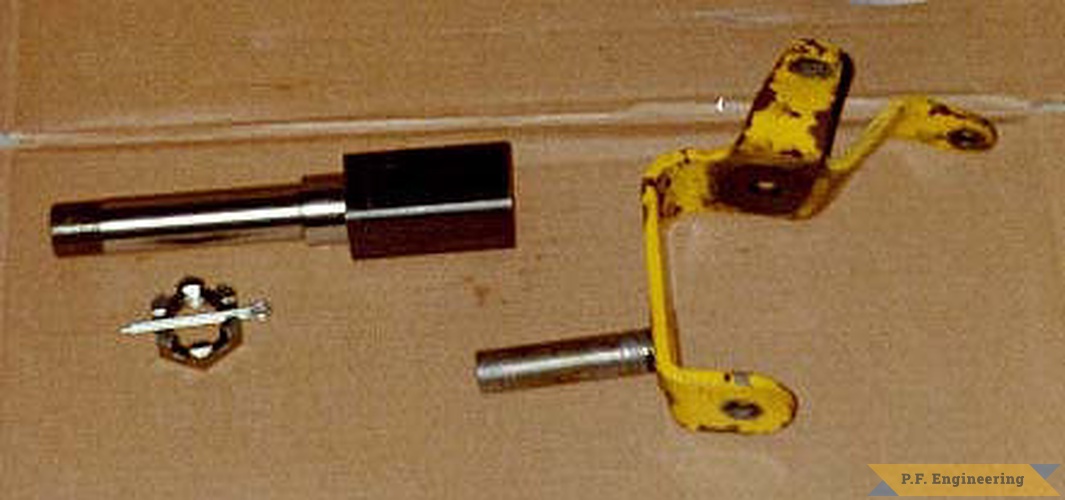

Start by cutting off the old spindle. Then, grind the surface of the spindle bracket smooth.

Step 2

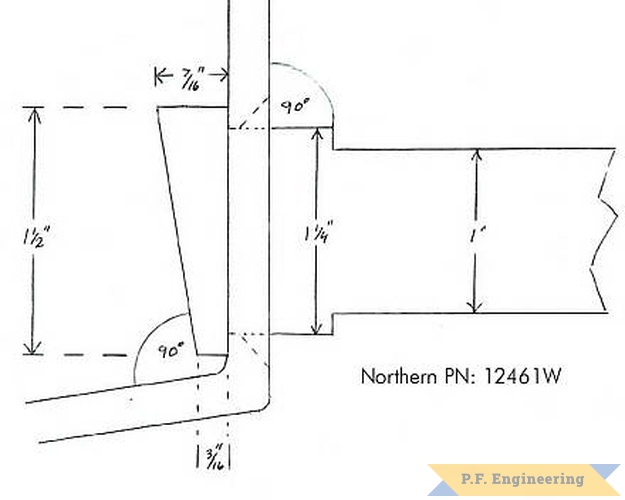

With a 1 1/4-inch bi-metal hole saw, cut a hole to accept the new stub axle shoulder. Remember to put a large chamfer on the outside of the spindle bracket for welding. Weld the inside and the outside.

Step 3

Box in the spindle bracket with 1/4-inch plate steel, and weld the inside and the outside.

Step 4

Make sure your outer weld is contained within the chamfer because you only have 1/8 of an inch between the spindle bracket and the new hub assembly.

Step 5

Install the hub, pack it with grease and check the clearances.

Step 6

Install your tires on the new rims. Then, you’re all set.

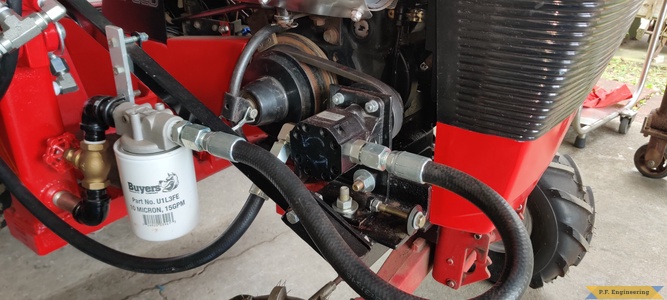

The Cub Cadet with newly upgraded 1000-pound front axles … Now you won’t have to wonder if the front end can take it.

What if you have L-shaped spindles?

Here is an idea from Doug H.

Another method from Stan C.

Jon’s solution

Before & After